Microscope

photographs

The

following pictures show microscopic photographs of the fully

cured PolymerMetal MM-metal oL-steelceramic magnified by a factor

of 100 and 500. Here the bonding between MM-metal oL-steelceramic

and metallic surfaces (steel or casting), which have been contaminated

by various applied oils before, has been analyzed. MM-metal oL-steelceramic

penetrates and absorbs oil, grease and fuel. The direct-MM-bonding

technology secures the direct and high solid bonding on contaminated

surfaces.

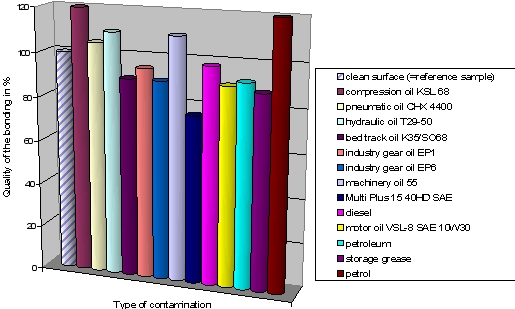

Bonding

on oily surfaces

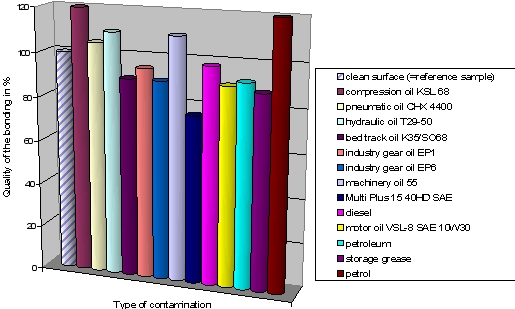

Tests have been carried out to evaluate the quality

of the bonding on different surfaces. At the reference test MM-metal

oL-steelceramic and Hardener yellow have been applied to a cleaned

(that means oil free) and roughened metal surface. The reference

value of 100% stands for the quality of the various determined

technical data during bending, shearing & hydraulic tests

after total curing time. Other values have been determined by

applying MM-metal oL-steelceramic on different contaminated metal

surfaces. The test results demonstrate that sometimes better

technical values were reached after application on oily metal

surfaces than on clean metal surfaces.

|

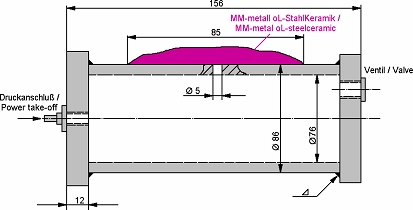

Testing

of pressure tightness

To be able to evaluate the quality of the application

of MM-metal oL-steelceramic on oily surfaces, tests have been

carried out at company M.A.N. under supervision of the classification

society Lloyds Register of Shipping. Here special test pipes

made off steel have been created according to the following drawing.

Around a leakage of a size of diameter 5 mm the metallic shiny

surface (Rz 65 µm) of the test cylinder was contaminated

with oil. Then the cold-curing MM-metal oL-steelceramic with

Hardener yellow was applied around the leakage. After full curing

of the PolymerMetal the test cylinder has been filled with a

liquid and pressure was built up. Then the system was checked

against pressure tightness.

Pressure

|

Test

cylinder temperature

|

Tool

|

Result

|

100

bar

|

20 °C

|

-

|

pressure

tight

|

150

bar

|

20 °C

|

-

|

pressure

tight

|

200

bar

|

20 °C

|

-

|

after

8 hours small leakage

|

In

the course of the time the research and development division

of MultiMetall was successful to continue optimising the material

MM-metal oL-steelceramic and new tests with same conditions

have been carried out at MultiMetall. The following results

were achieved:

Pressure

|

Test

cylinder temperature

|

Tool

|

Result

|

200

bar

|

20 °C

|

-

|

pressure

tight

|

300

bar

|

20 °C

|

-

|

pressure

tight

|

350

bar

|

20 °C

|

-

|

after

2 hours small leakage

|

150

bar

|

75 °C

|

-

|

pressure

tight

|

400

bar

|

75 °C

|

-

|

pressure

tight

|

The

pipe clip was fixed around the test cylinder in the area of

the leakage. Reinforcing elements as i.e. fibres or mats consisting

of glass or carbon have not been used. These would have increased

the physical strength essentially.

The

tests have been carried out at M.A.N. (test report No. 1731/82)

under supervision of Lloyds Register of Shipping (certificate

No. 301954) in 1982, the test at MultiMetall in 1995.

Extract

of the certificate: „The test results of MM-metal oL-steelceramic

may be classed as ranging from good to exceptionally good.

All test results were in support of the maker’s claim

that MM-metal oL-steelceramic will bond on oily surfaces with

a high degree of reliability.”

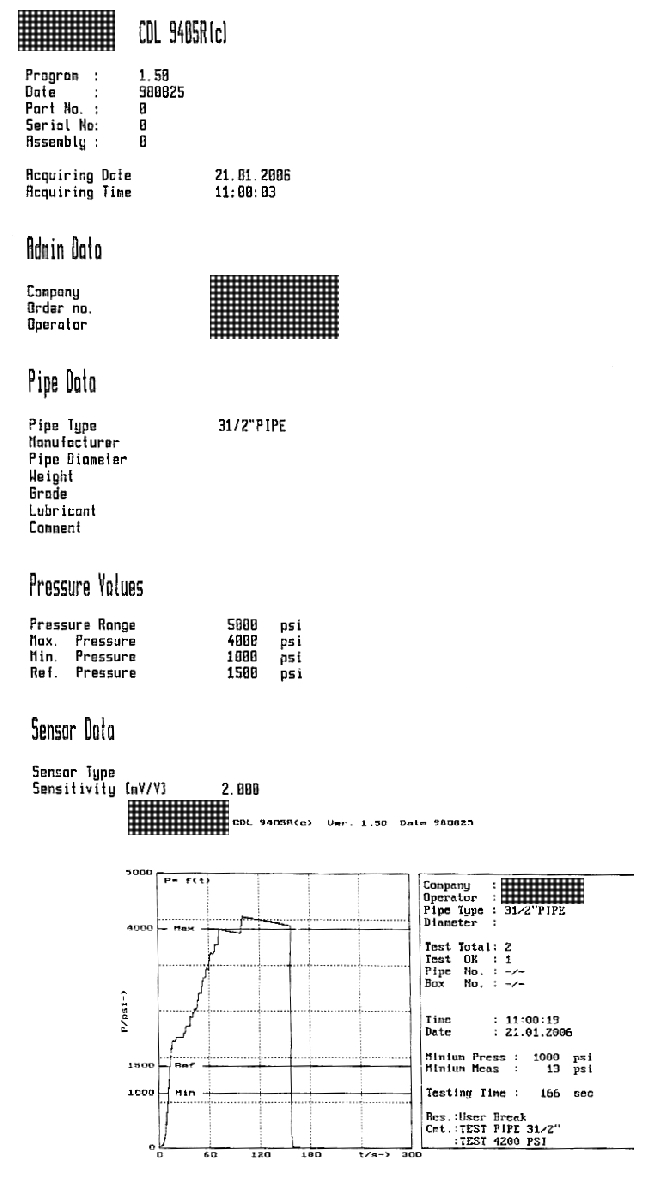

Practical example

At a service company, which is operating in the oil & gas

industry worldwide, pressure tests have been carried out with

MM-metal oL-steelceramic. The test piece was pressure tight up

to a tested pressure load of 4.000 psi (~ 275 bar).

Here are some

photographs incl. test records:

Above

mentioned information can be found in Technical

report No. 006  ,

too.

,

too.

Detailed

information can be received from our technical data sheets,

which are available for every product and which can be requested

by using the contact form.

=> Product

description MM-metal oL-steelceramic

Possible

product applications can be found at Worldwide

repairs.

MultiMetall® • PolymerMetall® • Ceramium® • Molymetall® • Sealium® • XETEX® • the

MetalExistenceCompany®